UV Printing Technology for Paper Packaging

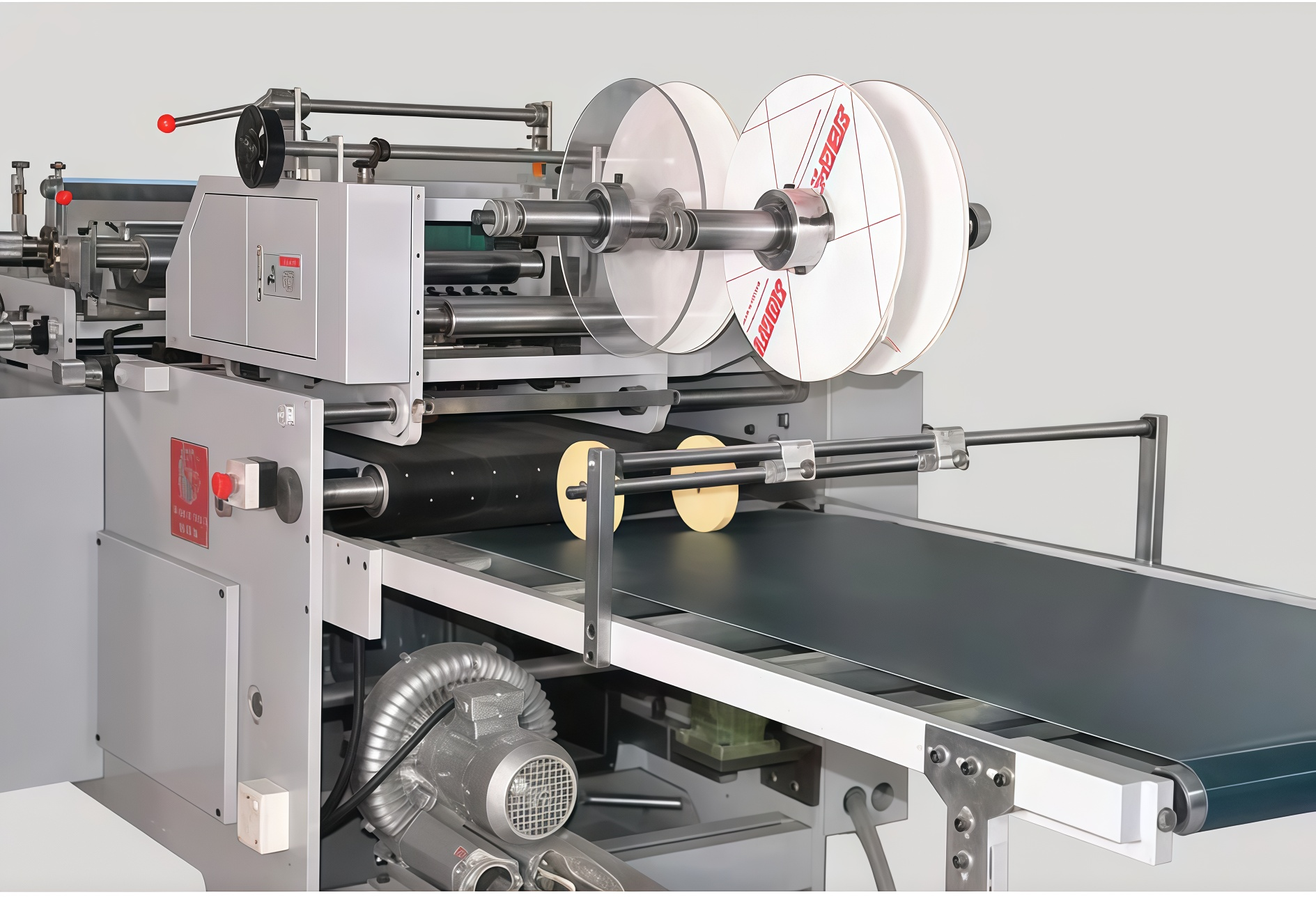

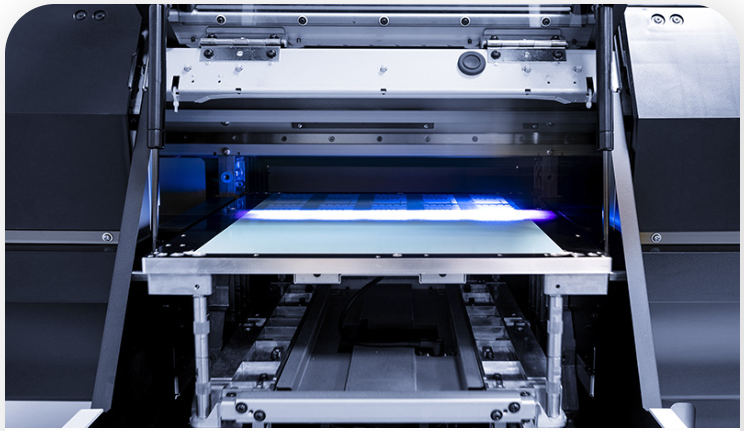

UV printing technology uses UV-curable inks to achieve high-precision, high-definition printing results on various material surfaces for paper packaging manufacturing. This process offers fast drying speed, vibrant colors, wear resistance, and water resistance, making it particularly suitable for producing high-end packaging, labels, and display materials in paper packaging manufacturing.

Our UV printers are equipped with advanced nozzle technology and color management systems, capable of accurately reproducing Pantone color systems to meet clients' strict requirements for color consistency in paper packaging. Meanwhile, UV curing technology is environmentally friendly and pollution-free, aligning with sustainable paper packaging manufacturing principles.

- Instant Drying for Efficient Production

- High Adhesion on Various Materials

- Environmentally Friendly UV Inks

- Wear & Water Resistant Finishes

- Precise Color Reproduction for Packaging