Does color management always make mistakes? The secret to full process control is hidden here!

The core points of color management

01/ The Goal and Significance of Color Management

The goal is to achieve "what you see is what you get", which means ensuring a high degree of color consistency between the design, printing, and final product.

02/ Key links and technologies

The monitor needs to be calibrated according to ISO 12646 standard to ensure accurate color display; Printing equipment needs to be calibrated regularly, with precise control of parameters such as ink density, dot pitch, printing pressure, etc; Commonly used color spaces such as RGB (design side), CMYK (printing side), Lab (objective standard), etc., achieve color conversion between devices through ICC characteristic files; Digital proofing can quickly verify color, while traditional proofing requires consideration of paper characteristics, ink quality, and the impact of post-processing on color, simulating the actual printing effect in advance. Using instruments such as spectrophotometers and density meters to measure color data, the Δ E value should be controlled within the industry standard range, i.e. Δ E<; 2.5.

03/ Standardized processes and specifications

(1) Client standardization: Designers need to use calibrated displays, and the design file must include spot color definitions, overlay information, etc., to ensure consistency with the printing data.

(2) Pre press file inspection: Review file format, font, color mode, etc., add auxiliary information such as color control bars and bleeding positions to provide accurate basis for printing.

(3) Sampling and mass production standards: New product sampling requires the determination of standard samples and upper and lower limit ranges; The first batch of mass production must strictly follow the sampling data to ensure the color consistency of the batch products.

04/ Challenges and Solutions Faced

(1) Material differences: To address color differences caused by different batches of paper and ink, strict incoming inspection and color adjustment curves are required.

(2) Environmental factors such as temperature, humidity, and light sources can affect the color presentation effect. It is necessary to produce in a constant temperature and humidity environment and use standard light sources for color evaluation.

(3) Balancing technology and cost: Advanced color management requires investment in equipment, software, and personnel training costs, but in the long run, it can improve efficiency and quality, and enterprises need to plan reasonably according to their own scale and needs.

Building a Color Management System

01/ Equipment calibration closed-loop

Using a spectrophotometer to achieve automatic calibration of the printing machine, the paper waste caused by traditional adjustment is reduced from 600-800 sheets to less than 50 sheets, while supporting color stability control of new substrates and special inks.

02/ Dynamic update of feature files

Record the device color gamut through ICC profile and update it monthly to cope with changes in paper and ink. Spot color management needs to be combined with Pantone color library and multi-color simulation technology, such as using 7-color ink sets instead of spot colors.

03/ Cross batch consistency

The closed-loop system automatically adjusts the ink keys by real-time scanning of the ribbon (2mm accuracy), with a tolerance range that can be controlled within Δ E ≤ 1.0, meeting the standards of brand customers.

04/ Multi process compatibility

The color conversion between digital proofing, flexographic printing, and offset printing requires pre-set feature files. Platforms such as Yinyayun can automatically complete color gamut mapping, reducing manual image adjustment time by more than 70%.

05/ Standardization Implementation Path

(1) Principle: Calibration → Characterization → Conversion.

(2) Toolchain configuration: Standard light source box, i1 Pro spectrophotometer, color management software.

(3) Process control: Establish a pH monitoring and color difference warning mechanism for the dampening solution to avoid color differences caused by environmental fluctuations.

Characteristics of different color management software

01/ GMG The core characteristics of

(1) High color accuracy: Adopting advanced color conversion algorithms, it can provide extremely high color reproduction, especially suitable for high-precision printing, such as trademarks, packaging, art works and other fields.

(2) Strong applicability: It is compatible with various types of printing machines, displays, scanners, and other devices, providing color consistency assurance for multiple devices.

(3) Professional color calibration function: Provides multiple color calibration solutions, especially in the high-end market. GMG's color management capabilities can meet professional color matching needs, ensuring high consistency between device output and design.

GMG The main advantages include:

(1) High precision color conversion: using ICC standards and precise algorithms for color matching, suitable for color conversion between various devices.

(2) Full process color control: providing a complete color control solution from design to printing, ensuring color consistency at every stage.

02/ CGS The core characteristics of

(1) Cross device color consistency: By calibrating displays, printers, and other devices, creating color profiles, and achieving color space conversion of images between different devices, it ensures consistency in the display effect of films on different projection devices (such as digital cinemas and giant screen systems).

(2) Standardized workflow: Combining hardware equipment, software tools, and standardized processes, it controls the entire process of color acquisition, editing, and output, suitable for printing, film and television production, and other fields. It can reduce manual proofreading costs, improve production efficiency and color reproduction accuracy.

(3) Real time color control: supports dynamic calibration of input and output devices, such as adjusting color parameters according to different paper and ink conditions, to achieve a "what you see is what you get" copying effect.

CGS The main advantages include:

(1) Advantages of software integration: built-in remote proofing function, direct call of server resources through the Internet, and more localized technology.

(2) Convenient operation: The color correction process is more streamlined, with outstanding performance in color reproduction, tone reproduction, and reducing dot enlargement.

(3) Market positioning: Mainly aimed at customers who purchase its software, with a more focused application scenario.

03/ EFI The core characteristics of

(1) Comprehensive solution: EFI provides a complete set of color management and production management solutions, suitable for different types of printing fields such as commercial printing, digital printing, and packaging printing.

(2) Ease of operation: EFI's software interface is simple and clear, making it very suitable for users who need to quickly get started, with a low operating threshold.

(3) The integration of digitalization and automation: EFI is particularly suitable for digital printing and automated production lines, which can help enterprises improve efficiency and reduce human errors.

EFI The main advantages include:

(1) Flexible workflow: EFI provides a highly integrated workflow platform that supports automated device settings and color management, making it ideal for modern commercial printing enterprises.

(2) Supporting multiple printing technologies: EFI not only supports traditional offset and flexographic printing, but is also particularly suitable for digital printing.

(3) Cost effectiveness: EFI's software solution comprehensively considers cost-effectiveness and can provide flexible pricing solutions suitable for printing enterprises of different sizes.

Color management on the client side

The implementation of color management on the client side is mainly based on the following reasons:

(1) Ensure color consistency: There are differences in color display and output between different devices such as mobile phones, computers, and printing machines.

(2) Maintaining brand image: For brand owners, accurate color management can ensure that brand logos, promotional materials, etc. have consistent colors across different channels (such as websites, print materials, advertisements), enhancing brand recognition and professionalism.

(3) Improving user experience: Proper color management can prevent visual fatigue or discomfort caused by color distortion, especially when viewing images, videos, or creating designs, providing a more realistic and comfortable visual experience.

(4) Adapting to the demand for wide color gamut: With the development of display technology and the popularity of wide color gamut screens, color management can ensure that content is displayed correctly on wide color gamut devices, while being compatible with traditional color gamut devices to avoid color loss or oversaturation.

(5) Support professional creation and production: Designers, photographers, and other professional users rely on color management to ensure accurate color transfer in different stages (shooting, editing, output) of their works, reducing rework costs caused by color deviations.

(6) Compliant with industry standards and trends: In industries such as design, printing, packaging, and film, color management is a necessary means to achieve standardized production and meet customer requirements for color accuracy. It helps to improve production efficiency and reduce waste rates.

ISO 12646 International standards specify the minimum requirements for color display characteristics during soft sampling, including uniformity, focusing performance, refresh rate, size, resolution, brightness, and observation conditions. We refer to displays that meet this requirement as standard displays. Use i1 Profiler color management software and i1 Pro2 spectrophotometer to calibrate the display. The specific steps are as follows:

(1) Set the color temperature of the monitor to D65 (to match the factory's D65 light source) and the Gamma value to 2.2.

(2) Measure and set the brightest and darkest values of the display.

(3) Measure the basic color blocks of the display.

(4) Generate ICC profile for the monitor and store it.

Color management on the sampling end

01/ Color Management for Digital Sampling

The core of implementing color management in digital prototyping is to solve the problem of color reproduction differences between devices and ensure color consistency from design to output.

(1) Basic requirements for standard adaptability

① Color matching requirements: ISO 12647-7, as a digital proofing standard, requires the printer's color gamut to cover the CMYK color gamut range of traditional printing (such as ISO 12647-2), and color gamut mapping and matching must be achieved through ICC characteristic files.

② Grey balance control: G7 calibration method is adopted to ensure that the L * a * b * value deviation Δ E in the neutral grey area is ≤ 1.5, and the order consistency is achieved by adjusting the TVI (dot enlargement curve).

(2) Key management processes

① Linearization calibration of equipment: Use a spectrophotometer to measure the field density and dot gain of the printing machine; Adjust the ink volume curve through the DFE digital front-end to achieve a 1% to 99% dot pitch error of ≤± 2%.

Explore our best-selling Custom Rigid Boxes and

Industrial Paper Rolls.

Factory-direct pricing for bulk orders with low MOQ options.

Featured OEM Packaging Projects & Wholesale Stock

Light pink Customized flip-top cardboard box

Blue and white Customized hinge cover hard box

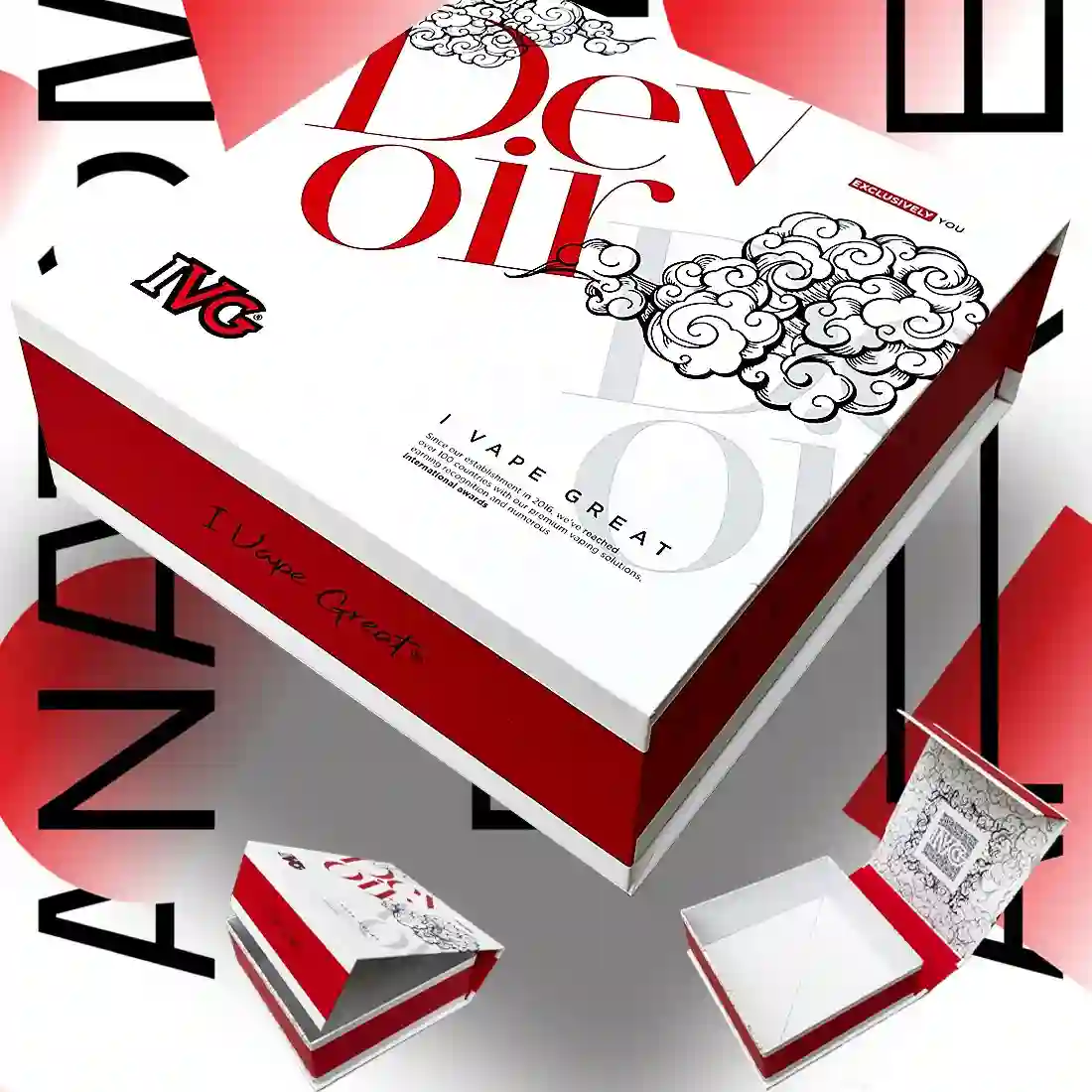

White background with red text Customized flip cover magnetic lock hard box

Dark blue Customized flip-top cardboard box

Lake green Customized flip-top cardboard box

Red Customized magnetic hard box

Customized magnetic hard box

Flip up magnetic hard box